长兴华强电子股份有限公司成立于1998年,是一家专业从事电子元器件制造与研发的高新技术企业。公司占地面积36000平方米,建筑面积25000平方米,现有工程技术人员55人,其中高级工程师1名,工程师15名。

CBB20A轴向金属化聚丙烯膜电容器

Axial-type Metallized Polypropylene film Capacitor

1.特征和用途 Features and usage

* 金属化聚丙烯膜,良好的自愈性

* 轴向引出,体积小,重量轻

* 聚酯胶带包裹,阻燃环氧树脂灌封(UL94V-0)

* 适用于定时、振荡、温度补偿、功率因数校正、开关电源耦合等电路。

* Metallized polypropylene film,excellent self-healing property

* Axial leaded,small size,light weight

* Wrapped with polyester adhesive tape and filled with flame-retardantresin (UL94 V-0)

* Suitable for timing,oscillator,temperature compensation,PFC and SMPS coupling circuit,etc.

2.技术特征 Features and usage

| 引用标准 Reference Standard | GB/T 10190(IEC 60384-16) |

| 气候类别 Climatic Category | 40/105/21 |

| 额定温度 Rated Temperature | 85℃ |

| 工作温度范围 Operating Temperature Range |

-40~105℃ ( 85 ~105℃: Decreasing factor 1.25% per℃ for UR) |

| 额定电压 UR Rated Voltage | 250/400/630/1000/1250V、160/200/250/350/400Vac |

| 电容量范围Capacitance Range | 0.001 μF~15.0 μF |

| 容量偏差 Capacitance Tolerance | ±5% (J) ±10% (K) ±20%(M) |

| 耐电压 Voltage Proof | 1.6UR (5s) |

| 绝缘电阻 RIns Insulation Resistance ( Rlns) | CN≤0.33μF: ≥15000MΩ CN>0.33μF: ≥5000s ( 20℃,100Vdc, 1min ) |

| 损耗角正切 tan & Dissipation Factor | ≤0.0100 (1kHz,20℃) |

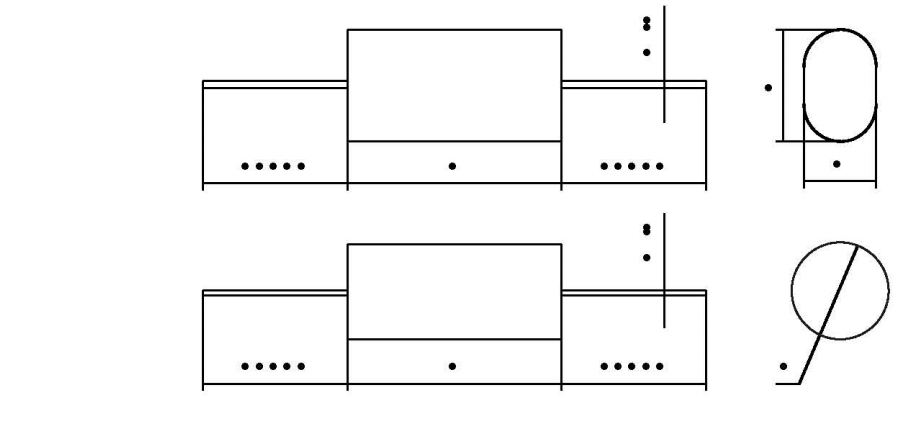

3.外型尺寸 Dimensions

单位(Unit :mm)

| 250Vdc (160Vac) | 400Vdc(200Vac) | ||||||||||

| CN (μF) |

Cylinder | Flat | L±1.0 (mm) |

d±0.05 (mm) |

CN (μF) |

Cylinder | Flat | L±1.0 (mm) |

d±0.05 (mm) |

||

| D±1.0 (mm) |

H±1.0 (mm) |

T±1.0 (mm) |

D±1.0 (mm) |

H±1.0 (mm) |

T±1.0 (mm) |

||||||

| 0.047 | 5.5 | 15.0 | 0.6 | 0.033 | 5.5 | 15.0 | 0.6 | ||||

| 0.068 | 6.0 | 15.0 | 0.6 | 0.047 | 6.5 | 15.0 | 0.6 | ||||

| 0.1 | 7.0 | 15.0 | 0.8 | 0.068 | 7.0 | 15.0 | 0.8 | ||||

| 0.15 | 8.0 | 15.0 | 0.8 | 0.1 | 7.0 | 20.0 | 0.8 | ||||

| 0.22 | 7.5 | 20.0 | 0.8 | 0.15 | 8.0 | 20.0 | 0.8 | ||||

| 0.33 | 9.0 | 20.0 | 0.8 | 0.22 | 9.0 | 20.0 | 0.8 | ||||

| 0.47 | 8.5 | 27.0 | 0.8 | 0.33 | 9.0 | 27.0 | 0.8 | ||||

| 0.68 | 10.0 | 27.0 | 0.8 | 0.47 | 10.0 | 27.0 | 0.8 | ||||

| 1.0 | 12.0 | 27.0 | 0.8 | 0.68 | 12.0 | 27.0 | 0.8 | ||||

| 1.5 | 12.5 | 33.0 | 0.8 | 1.0 | 12.5 | 33.0 | 0.8 | ||||

| 22 | 14.5 | 33.0 | 0.8 | 1.5 | 15.0 | 33.0 | 0.8 | ||||

| 3.3 | 17.5 | 33.0 | L0 | 2.2 | 17.5 | 33.0 | 1.0 | ||||

| 4.7 | 18.0 | 43.0 | L0 | 3.3 | 18.5 | 43.0 | 1.0 | ||||

| 6.8 | 21.5 | 43.0 | L0 | 4.7 | 21.5 | 43.0 | 1.0 | ||||

| 10.0 | 21.5 | 57.0 | L0 | 6.8 | 21.5 | 57.0 | 1.0 | ||||

| 15.0 | 25.5 | 57.0 | L0 | 10.0 | 25.5 | 57.0 | 1.0 | ||||

| 630Vdc(250Vac) | 1000Vdc(350Vac) | ||||||||||

| CN (μF) |

Cylinder | Flat | L±1.0 (mm) |

d±0.05 (mm) |

CN (μF) |

Cylinder | Flat | L±1.0 (mm) |

d±0.05 (mm) |

||

| D±1.0 (mm) |

H±1.0 (mm) |

T±1.0 (mm) |

D±1.0 (mm) |

H±1.0 (mm) |

T±1.0 (mm) |

||||||

| 0.01 | 5.5 | 15.0 | 0.6 | 0.0047 | 5.5 | 15.0 | 0.6 | ||||

| 0.015 | 6.0 | 15.0 | 0.6 | 0.0068 | 6.5 | 15.0 | 0.6 | ||||

| 0.022 | 7.0 | 15.0 | 0.8 | 0.01 | 7.5 | 15.0 | 0.8 | ||||

| 0.033 | 7.0 | 20.0 | 0.8 | 0.015 | 8.5 | 15.0 | 0.8 | ||||

| 0.047 | 8.0 | 20.0 | 0.8 | 0.022 | 8.0 | 20.0 | 0.8 | ||||

| 0.068 | 9.0 | 20.0 | 0.8 | 0.033 | 9.0 | 20.0 | 0.8 | ||||

| 0.1 | 8.5 | 27.0 | 0.8 | 0.047 | 10.5 | 20.0 | 0.8 | ||||

| 0.15 | 10.0 | 27.0 | 0.8 | 0.068 | 9.5 | 27.0 | 0.8 | ||||

| 0.22 | 12.0 | 27.0 | 0.8 | 0.1 | 11.5 | 27.0 | 0.8 | ||||

| 0.33 | 12.5 | 33.0 | 0.8 | 0.15 | 12.0 | 33.0 | 0.8 | ||||

| 0.47 | 14.5 | 33.0 | 0.8 | 0.22 | 14.0 | 33.0 | 0.8 | ||||

| 0.68 | 17.0 | 33.0 | 1.0 | 0.33 | 16.5 | 33.0 | 1.0 | ||||

| 1.0 | 17.5 | 43.0 | 1.0 | 0.47 | 17.5 | 43.0 | 1.0 | ||||

| 1.5 | 21.0 | 43.0 | 1.0 | 0.68 | 20.5 | 43.0 | 1.0 | ||||

| 2.2 | 24.5 | 43.0 | 1.0 | 1.0 | 20.5 | 57.0 | 1.0 | ||||

| 3.3 | 25.0 | 57.0 | 1.0 | 1.5 | 24.5 | 57.0 | 1.0 | ||||

| 1250Vdc(400Vac) | |||||||||||

| CN (μF) |

Cylinder | Flat | L±1.0 (mm) |

d±0.05 (mm) |

|||||||

| D±1.0 (mm) |

H±1.0 (mm) |

T±1.0 (mm) |

|||||||||

| 0.0033 | 6.0 | 15.0 | 0.6 | ||||||||

| 0.0047 | 6.5 | 15.0 | 0.6 | ||||||||

| 0.0068 | 7.5 | 15.0 | 0.8 | ||||||||

| 0.01 | 8.5 | 15.0 | 0.8 | ||||||||

| 0.015 | 7.5 | 20.0 | 0.8 | ||||||||

| 0.022 | 8.5 | 20.0 | 0.8 | ||||||||

| 0.033 | 10.5 | 20.0 | 0.8 | ||||||||

| 0.047 | 9.5 | 27.0 | 0.8 | ||||||||

| 0.068 | 11.0 | 27.0 | 0.8 | ||||||||

| 0.1 | 13.0 | 27.0 | 0,8 | ||||||||

| 0.15 | 13.5 | 33.0 | 0.8 | ||||||||

| 0.22 | 16.0 | 33.0 | 1.0 | ||||||||

| 0.33 | 17.0 | 43.0 | 1.0 | ||||||||

| 0.47 | 19.5 | 43.0 | 1.0 | ||||||||

| 0.68 | 20.0 | 57.0 | 1.0 | ||||||||

| 1.0 | 23.0 | 57.0 | 1.0 | ||||||||

| 1.5 | 27.5 | 57.0 | 1.0 | ||||||||

备注Note:

1.Cylinder是指圆柱形,Flat是指压扁形,其中压扁形的高度H和厚度T可以按需调整。

2.上表中未包含的产品规格可根据用户要求进行设计和制造。